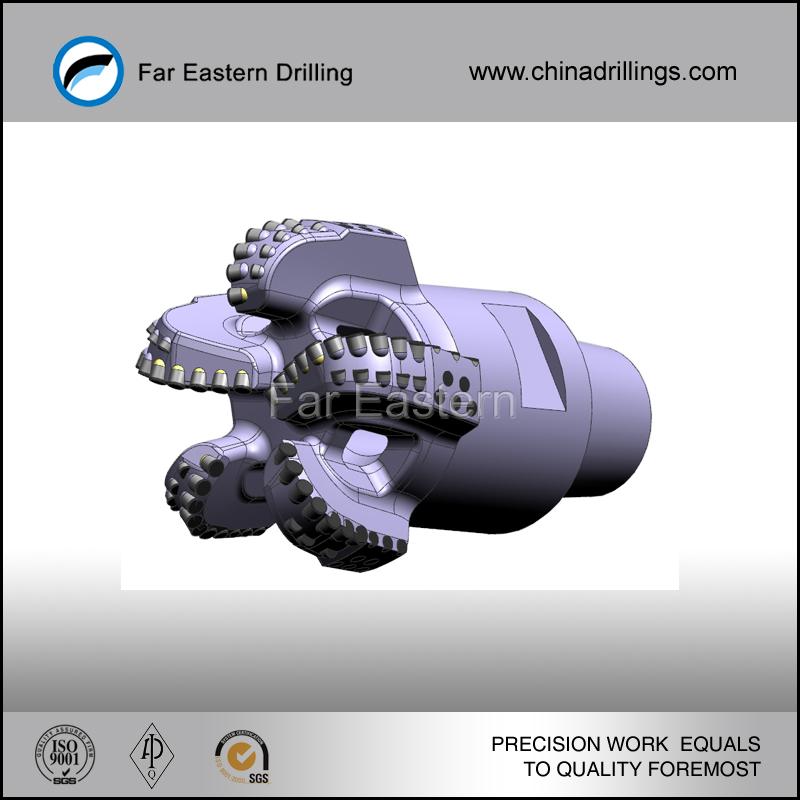

2022 High quality Milled Tooth Drill Bits - Tricone bit factory IADC126 26 inches (660mm) – FAR EASTERN

2022 High quality Milled Tooth Drill Bits - Tricone bit factory IADC126 26 inches (660mm) – FAR EASTERN Detail:

![]()

Product Description

![]()

Tricone bit Included Steel Tooth (also referred to as milled tooth) bits and Tungsten Carbide Insert (TCI) bits.

TCI bits are much more durable than Steel Tooth ones, but carry a higher cost to manufacture.

Both these two groups of Tricone Bits are available with

(1) Open Bearing or Sealed Bearing

(2) Roller Bearing or Friction Bearing (Journal Bearing)

(3) Gage Protected or Non-Gage Protected, etc

Mill tooth tricone drill bits have very high drilling rates in soft formations.

Drilling Tools can hard face the milled teeth so that they sharpen themselves while drilling.

Milled tooth tricone bits are designed for very soft to medium hardness formations.

Open Bearing mill tooth Tri-Cone roller cone bit can come with or without gauge protection.

These are less expensive than sealed bearing but they typically do not last as long.

Sealed Bearing mill tooth tri cone bit with or without gauge protection

These are the best preforming and longest lasting style of tri cone on the market.

![]()

Product Specification

Steel tooth tricone bits are also named milled tooth tricone bit, “steel” means the teeth material is steel, actually it is a type of special steels 15MnNi4Mo and the surface of steel material is hard faced by Tungsten Carbide to increase wear resistance

Milled means the teeth is machined by milling machine, so steel tooth tricone bits have another names “mill tooth tricone bits” or “milled tooth tricone bits”.

26 inches is always diameter of the first hole in deep well drilling, the formations are always soft in shallow section, so 26″ is widely used in worldwide

Choose the correect and suitable IADC code to reach the best cost-effective, we are pleasant to choose the right tricone bits according to your geological information.

Far Eastern Drilling attends exhibitions in many countries worldwide, hopefully to talk with you face to face in near future.

|

Basical Specification |

|

|

Size of Rock Bit |

26″ |

|

660 mm |

|

|

Bit Type |

Steel Tooth Tricone Bit/ Milled tooth Tricone Bit |

|

Thread Connection |

7 5/8 API REG PIN |

|

IADC Code |

IADC 126 |

|

Bearing Type |

Journal Sealed Roller Bearing |

|

Bearing Seal |

Rubber Seal |

|

Heel Protection |

Unvailable |

|

Shirttail Protection |

Available |

|

Circulation Type |

Mud Circulation |

|

Drilling Condition |

Rotary drilling,high temp drilling,deep drilling,motor drilling |

|

Nozzles |

3 |

|

Operating Parameters |

|

|

WOB (Weight On Bit) |

299,64-126,057 lbs |

|

198-561KN |

|

|

RPM(r/min) |

60~180 |

|

Formation |

Soft formations with low compressive strength and high drillability,such as mudstone,gypsum,salt,soft limestone ,etc.

|

![]()

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for 2022 High quality Milled Tooth Drill Bits - Tricone bit factory IADC126 26 inches (660mm) – FAR EASTERN , The product will supply to all over the world, such as: Israel, Angola, Poland, Many years of work experience, we have now realized the importance of providing good quality products and solutions and whole heartedly before-sales and after-sales services. problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Problems can be quickly and effectively resolved, it is worth to be trust and working together.