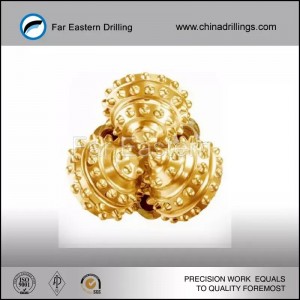

API Deep mining well tricone bits IADC832 12.25″ 311mm

Product Description

Wholesale mining well tricone drilling bits with discounted price from China factory.

Bit Description:

IADC: 832-TCI standard open air-cooled bearing bit for extremely hard and abrasive formations.

Compressive Strength:

100-150 MPA

14,500-23,000 PSI

Ground Description:

Hard, well-compacted rocks such as :hard silica limestones,quarzite streaks,pyrite ores,hematite ores,magnetite ores,chromium ores,phosphorite ores,and granites.

We can offer mining tricone rock drill bits in a variety of sizes and most of IADC Codes.

Product Specification

|

Basical Specification |

||

|

IADC Code |

IADC832 |

|

|

Size of Rock Bit |

9 5/8 inches |

12 1/4 inches |

|

244.5mm |

311mm |

|

|

Thread Connection |

6 5/8” API REG PIN |

|

|

Product Weight: |

65KG |

98KG |

|

Bearing Type: |

Roller-Ball-Roller-Thrust Button/Open Bearing |

|

|

Circulation Type |

Jet Air |

|

|

Operating Parameters |

||

|

Weight on Bit: |

48,125-77,000Lbs |

61,250-98,000Lbs |

|

Rotary Speed: |

80-50RPM |

|

|

Air Back Pressure: |

0.2-0.4 MPa |

|

|

Ground Description: |

Hard, well-compacted rocks such as: hard silica limestone, quarzite streaks, pyrite ores, hematite ores, magnetite ores, chromium ores, phosphorite ores, and granite.

|

|

CUTTING STRUCTURE:

IADC:832-TCI standard open air-cooled bearing roller bit

CUTTING STRUCTURE:

Inner and Nose Rows:Ovoid

Gage Rows:Ovoid

Gage Bevel Protection:Round

Pin Connection:6 5/8"API

Metric Bia Diameter:311mm

Product Weight:98kg

Designed for extremely hard and abrasive formations with high compressive strengths such as magnetite quartzite, quartzite, granite.

Application: 55,000-66,000Psi

SHIRTTAIL PROTECTION:

Hardmetal and wear resistant carbide on shirttail lip and lug.

PRODUCT SPECIFICATION:

IADC Code:832

Bearing Type:Roller-Ball-Roller-Thrust Button/Opened Bearing

Circulation Type: Jet Air

OPERATING SUGGESTIONS:

Weight on Bit:61,250-98,000lbs

Rotary Speed:80-50RPM

Air Back Pressure:0.2-0.4MPa

Far Eastern rotary tricone bits adopt optimally -designed bearing structures and tungsten carbide inserts to withstand the extreme challenge of modern mining applications.Design engineers are evolving to increase drilling performance.